Why Sensor Structure Often Overlooked in Outdoor Lighting Engineering?

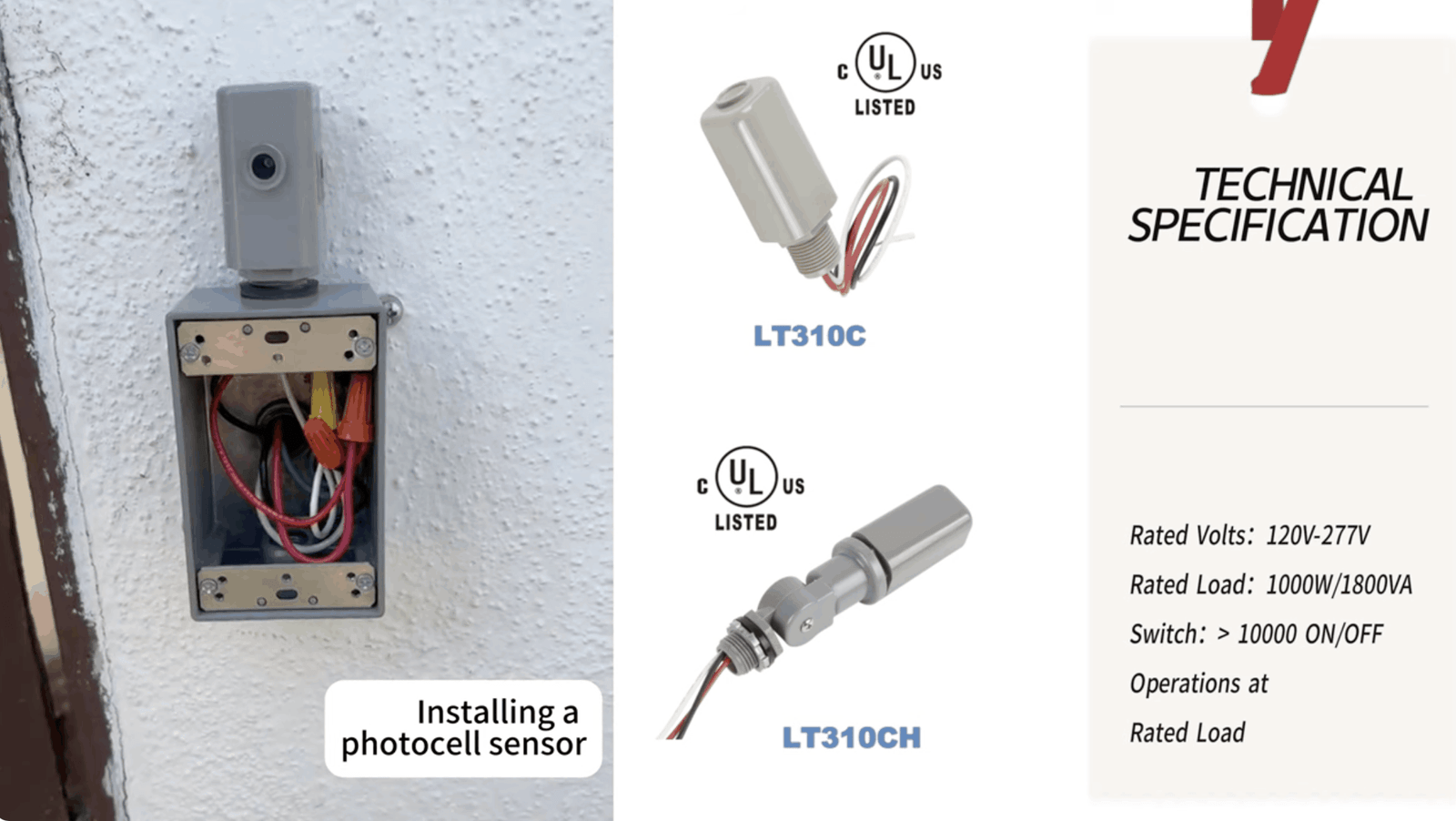

When choosing a photo control device for outdoor illumination systems, engineers customarily prioritize electrical parameters such as voltage ratings, load capacity, switching thresholds, and ingress defense levels. Although these factors are irrefutably crucial, structural design is often taken as a secondary or even insignificant concern. In actuality, outdoor lighting sensor engineering is not administered by electrical performance only. Mechanical structure openly effects how efficiently a sensor performs once positioned in the field.

The structural configuration of a photo control decides how it interacts with its physical atmosphere. Orientation, exposure angle, and positional stability all impact how environmental light is sensed. Overlooking these factors can result in unreliable operation, commissioning postponements, and avoidable preservation costs. This is particularly true when matching fixed vs adjustable sensor structures, where the mechanical design thinking fundamentally shapes system behavior.

What Is the Core Structural Difference Between Fixed and Adjustable Sensors?

At the most basic level, the difference between fixed and adjustable sensors deceits in whether the light-sensing element can be reoriented after installation. In a photo control structure comparison, this dissimilarity seems mechanical, but its repercussions spread deeply into functioning dependability and lifespan performance.

Fixed sensor structures lock the orientation of the sensor at the time of engineering. Once installed, the sensor’s field of view cannot be altered devoid of eliminating and reinstalling the device. Adjustable sensor structures, by contrast, permit the sensing head to revolve or pivot relative to its mounting base. This adjustability converts orientation from a rigid restraint into a tunable variable.

How Do Fixed Sensor Structures Influence Installation Outcomes?

Fixed sensor designs assume that installers can attain perfect orientation during mounting. This assumption may hold in organized environs, but outdoor illumination installations hardly offer such constancy.

In fixed designs, these restraints become undying. If the sensor faces reflective surfaces, neighboring luminaires, or unpremeditated non-natural light sources, false activating can happen. Because the orientation cannot be attuned, resolving the problem often needs physical reinstallation.

In this fixed vs adjustable sensor discussion, fixed structures efficiently embed orientation risk into the installation phase. Any mistake or conciliation made at that stage is carried forward all through the system’s working life.

Why Do Adjustable Sensor Structures Acknowledge Real-World Variability?

Adjustable sensor structures are made with the assumption that perfect situations are rare instead of typical. Rather than demanding accuracy during installation, they take inconsistency as a central design input.

This thinking is fundamental to controle de haste giratória design, where the sensor body can revolve autonomously of the mounting base. The adjustment affects only the direction from which light is sensed; electrical characteristics and sensitivity stay unchanged.

By decoupling orientation from mounting restraints, adjustable structures permit engineers and installers to react to site-specific situations devoid of altering the electrical system. This methodology line up closely with real-world outdoor lighting sensor engineering, where ecological volatility is the norm.

How Does Sensor Structure Affect Commissioning Efficiency?

Comissionamento is where structural dissimilarities become most evident. With fixed sensors, unanticipated behavior—such as lights cycling wrongly—often leads to troubleshooting efforts focused on wiring, sensitivity settings, or electrical compatibility. Adjustable sensors streamline this process. Installers can perceive actual behavior under actual illumination settings and tune the sensor’s orientation consequently. This converts commissioning from a trial-and-error exercise into an organized optimization process.

In a photo control structure comparison, flexible designs constantly decrease commissioning time and ambiguity, particularly on sites with numerous luminaires.

How Do Structural Differences Impact System-Level Consistency?

Big outdoor illumination projects unavoidably consist of variation. Even when using homogeneous poles and fixtures, minor variances in mounting angle or location are inevitable. Fixed sensor structures intensify these variations into unreliable performance across the site.

Modifiable structures alleviate this problem by letting every sensor to be aligned to a common reference direction. This ability is particularly valued in highway, parking areas, and campus illumination applications, where unvarying behavior is important.

How Does the LT210CH Series Illustrate Adjustable Sensor Advantages?

Produtos como LT210CH series validate how flexible structures support manufacturing constancy without increasing system complication. As swivel wire-in thermal type photo controls, these devices incorporate orientation adjustability directly into the mechanical design.

Instead of requiring numerous product variations or custom mounting accessories, the modifiable structure permits a single model to accommodate varied site situations. Within a photo control structure comparison, the LT210CH series shows how mechanical suppleness can co-occur with electrical constancy and ecological vigor.

What Are the Long-Term Performance Implications of Sensor Structure?

Outdoor environs are not stagnant. New light sources may be added, reflective surfaces may appear, and cyclical sun angles can change exposure patterns. Fixed sensor de fotocélula structures are characteristically incompetent to acclimatize to these changes.

When performance degradation take place, the only remedial option is physical interference—often involving employment, equipment, and downtime. Modifiable sensors, by contrast, can be readjusted during preservation visits to reinstate planned behavior.

This flexibility prolongs service life and decreases maintenance occurrence, directly influencing total cost of ownership. In long-run fixed vs adjustable sensor assessments, adaptable designs constantly offer improved lifespan economics.

Does Adjustability Compromise Stability or Durability?

A common apprehension is whether adjustable mechanisms introduce mechanical weakness. From an manufacturing viewpoint, adjustability does not characteristically decrease durability. Well-designed swivel mechanisms balance controlled movement with safe locking and ecological sealing.

In contemporary swivel stem control design, the adjustment range is cautiously engineered to uphold constancy under vibration, wind loading, and heat cycling.

How Should Engineers Evaluate Fixed vs Adjustable Sensor Structures?

The choice between these structures is basically a manufacturing decision. Fixed designs highlight simplicity at the expense of adaptableness. Adjustable designs prioritize flexibility and long-lasted dependability.

In most outdoor applications, where inconsistency and change are predictable, adjustable sensor structures offer quantifiable benefits in commissioning proficiency, system constancy, and lifespan cost control.

Fixed vs Adjustable Sensor Structures: Key Engineering Differences

| Engineering Aspect | Fixed Sensor Structure | Adjustable Sensor Structure |

| Orientation Control | Locked after installation | Tunable after installation |

| Installation Risk | Alto | Baixo |

| Commissioning Effort | Trial-and-error | Controlled optimization |

| System Consistency | Variable across site | Uniform alignment possible |

| Long-Term Adaptability | Nenhum | Alto |

How Do Adjustable Designs Support Engineering Scalability?

| Requisitos do projeto | Fixed Design Impact | Adjustable Design Impact |

| Site variability | Performance inconsistency | Orientation compensation |

| Maintenance needs | Reinstalação necessária | Realinhamento simples |

| Inventory management | Multiple variants needed | Single adaptable model |

| Lifecycle cost | Higher over time | Lower total cost |

How Does Lead-Top Integrate Structure into System Performance?

At Lead-Top, mechanical structure is taken as a central performance parameter instead of a second thought. Through adaptable designs such as Swivel Stem Control, we assist engineers lessen installation risk, attain constant commissioning outcomes, and uphold dependable performance all through the product lifespan.

In applied manufacturing terms, the choice between fixed and adjustable sensor structures is a choice between inflexible assumptions and adaptive design. For most contemporary outdoor illumination projects, adaptability wins.