Introdução

Embora os conectores Zhaga frequentemente recebam atenção por seus padrões de interface, a humilde porca determina silenciosamente se um sistema de iluminação dura 5 anos ou 25. Zhejiang Lead top ElectricNossa experiência em milhares de projetos globais de controle de iluminação prova que a seleção de materiais para esses pequenos componentes exige muito pensamento.

Porcas de zinco: a ferramenta mais econômica

Vantagem de preço

Custo do material: 33-50% mais barato que o aço inoxidável

Ideal para projetos municipais que exigem mais de 1 milhão de unidades

Excelência em Fabricação

Produção de fundição sob pressão 5x mais rápida (verificado pelos dados de produção da Lead Top)

Taxa de aprovação 99%+ para geometrias complexas

Flexibilidade no tratamento de superfície

O revestimento de níquel (5-8 μm) atinge resistência à névoa salina por 72 horas

Cromagem para maior proteção contra chuva ácida urbana (pH≥4,5)

▶ eucabeça no topo Caso:

Projeto de iluminação pública inteligente da capital provincial de 2022:

Utilizamos nossas porcas de zinco + cromagem

Nenhuma corrosão relatada em inspeções de 3 anos

Economia de custos do 35% em comparação ao aço inoxidável

Arruelas de pressão de dentes internos de aço inoxidável: o desempenho premium

Desempenho em ambientes extremos

Aço inoxidável 304/316 passa no teste de névoa salina 5% de 2000h

Sem formação de ferrugem vermelha (vs 120h para zinco revestido)

Superioridade Mecânica

Resistência à tração de 520 MPa (zinco: 280 MPa)

Crítico para pontes/túneis com riscos de vibração

Economia do Ciclo de Vida

Dados do projeto de Dubai: 60% com custos de manutenção mais baixos

Vida útil de 30 anos em ambientes costeiros

▶ eucabeça no topo Vantagens:

Opções de material duplo sem restrições de MOQ

Consulta gratuita sobre seleção de materiais

Soluções personalizadas para aplicações especiais

O Método de Seleção 4Q

Responda estas perguntas para escolher corretamente:

- Ambiente: C4 (industrial/costeiro) ou CX (extremo)? → Aço inoxidável

- Orçamento: Precisa de redução de custo >15%? → Zincagem + galvanoplastia

- Vida útil: <10 anos ou ≥15 anos?

- Risco de vibração: Alto estresse mecânico? → Inoxidável

- Conclusão: Engenharia de precisão, não apenas produtos

Na Lead Top projetamos soluções onde:

✓ Cada $0.8 premium para aço inoxidável compra décadas de confiabilidade

✓ Cada liga de zinco economiza fundos em infraestrutura extra (por exemplo, 500 m a mais de iluminação)

Por que clientes globais escolha-nos:

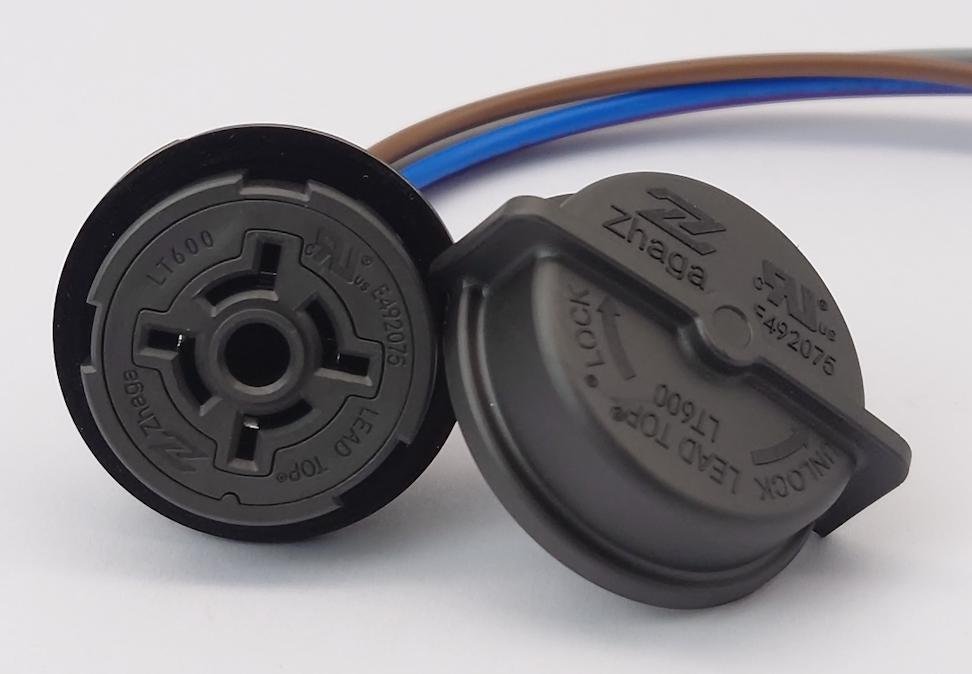

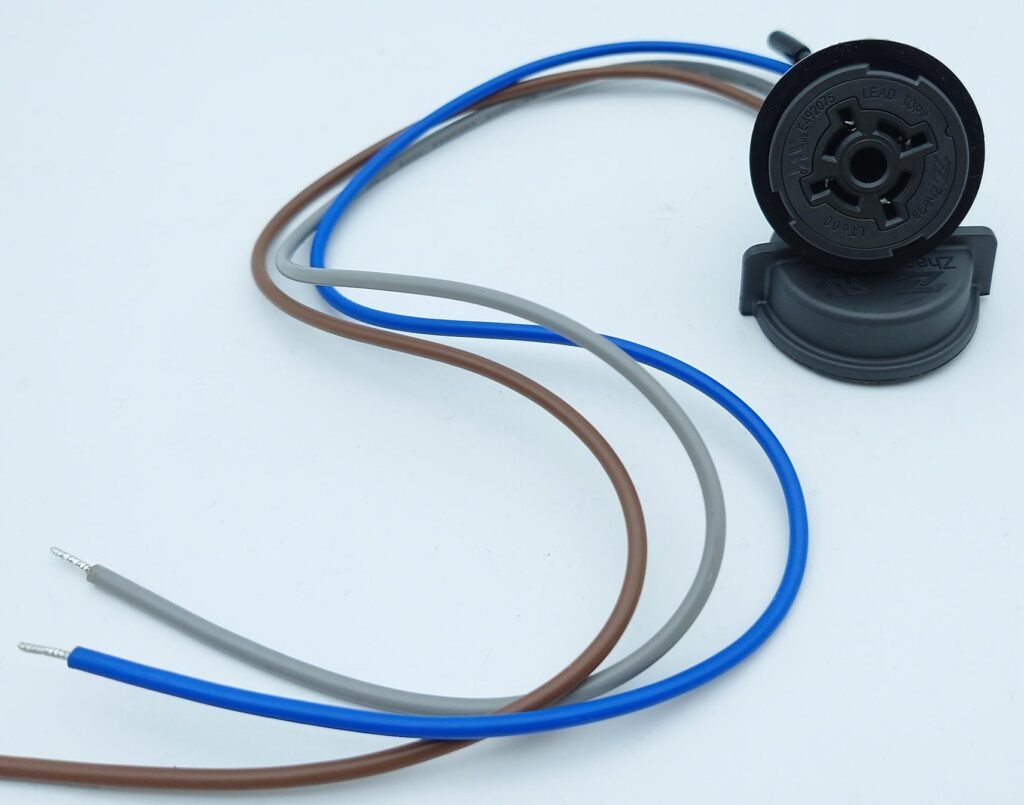

Componentes compatíveis com Zhaga com experiência em materiais incomparável

Do protótipo à produção em massa com barreiras zero de MOQ

Ferramentas de seleção baseadas em dados para TCO ideal