In illumination control and sensing applications, the phrase installation flexibility is used recurrently—but hardly explored in detail. Numerous products are endorsed as easy to install, yet once they reach the job site, installers every so often realize that actual surroundings do not follow design assumptions. This gap between anticipation and actuality is where a rotatable sensor head proves its correct value.

A rotatable sensor head, particularly when allowed by swivel stem control, does more than rotate. It basically changes how a product acclimatizes to random installation circumstances. Rather than compelling installers to compensate for inflexible hardware, the product itself becomes flexible.

This design swing is subtle in appearance but noteworthy in influence, predominantly in outdoor photo control applications where ecological variables continuously influence performance.

What Installation Challenges Do Fixed-Direction Sensors Create in the Field?

Traditional fixed-direction photocell sensors are manufactured around a single assumption: that mounting surfaces are smooth, orientation is anticipated, and nearby light sources are known in advance. In actual projects, these assumptions hardly hold factual.

Light poles might lean to some extent, walls may face unintentional directions, and neighboring reflective surfaces can transmit light toward the sensor. When a fixed sensor is locked into one orientation, even small deviances can create wrong light detection.

These restrictions decrease installation flexibility and every so often lead to late shutoff, untimely activation, or recurrent cycling. Once fitted, rectifying these problems usually needs untying the base or reinstalling the device—both time taking and expensive actions.

How Does a Rotatable Sensor Head Change the Installation Experience?

A rotatable sensor head contraries the traditional installation logic. Rather than demanding perfect alliance during mounting, it permits orientation to be optimized later.

With swivel stem control, installers can firmly mount and wire the device first, then rotate the sensor body to match actual environmental settings. This parting of mechanical installation from directional arrangement considerably increases proficiency and accurateness.

Instead of adjusting the environs to the product, the product adjusts to the surroundings. This methodology decreases stress during installation and rises confidence that the system will perform as anticipated.

Why Is Swivel Stem Control Critical to Sensor Adjustability?

While rotation alone can exist in some designs, swivel stem control guarantees that adjustment is constant, measured, and repeatable. The swivel stem forms a vigorous mechanical joint among the mounting base and the sensor body.

This design permits angular and directional adjustment devoid of untying the base or compromising mechanical reliability. Once the anticipated orientation is attained, the sensor remains fixed—even under vibration, wind load, or thermal expansion.

In applied terms, swivel stem control converts adjustment from a risky conciliation into a dependable feature.

Why Is Installation Flexibility Especially Important in Outdoor Photo Control?

Outdoor illumination environs are among the most composite sensing environments. Street illumination, parking lots, industrial courtyards, and commercial lands every so often comprise of numerous overlapping light sources.

An outdoor photo control sensor that faces the incorrect direction may sense reflected light from neighboring luminaires, signage, or building surfaces. This can lead to inappropriate switching behavior that weakens system proficiency.

A rotatable sensor head permits installers to redirect the sensing window away from interfering areas and toward correct environmental light. This simple adjustment considerably improves sensing accurateness and functioning dependability.

Installation mistakes often result from hurried decisions made before ecological settings are fully understood. Fixed sensors compel installers to commit to a sensing direction too early.

By distinction, a rotatable sensor head supports a two-step workflow:

- Safe installation and wiring

- Real-life directional fine-tuning

This methodology decreases guesswork and reduces the risk of misalignment. Consequently, commissioning becomes quicker, and remedial actions are less frequent.

What Makes the LT210CH Series a Practical Example of This Design Philosophy?

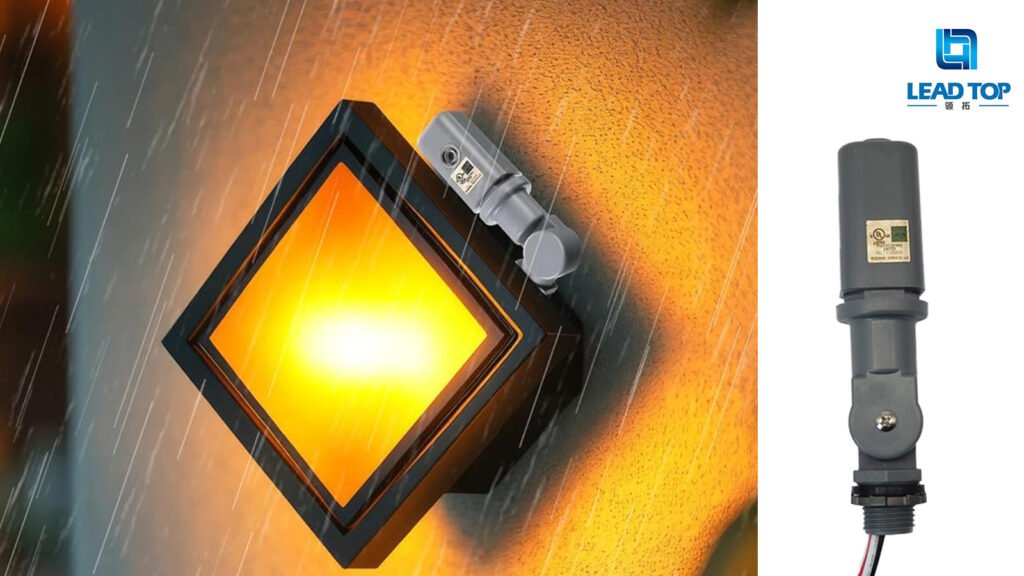

The LT210CH series from Lead-Top proves how a rotatable sensor head and swivel stem control interpret into real-life benefits.

Manufactured specially for outdoor photo control, the LT210CH series accommodates wide-ranging mounting positions, comprising poles, walls, and enclosures. Irrespective of installation angle, the sensor can be line up exactly with actual lighting situations.

This adaptableness permits one product family to serve numerous applications devoid of surrendering performance, decreasing the need for specialized models.

How Does a Rotatable Sensor Head Improve Project-Level Predictability?

From a project management viewpoint, ambiguity is expensive. When sensor orientation must be perfect on the first attempt, delays and rework become common.

Installation flexibility provided by a rotatable sensor head decreases dependence on assumptions during planning. Installers can adjust on site, decreasing commissioning time and improving schedule dependability.

In large-scale dispositions, these incremental proficiencies compound, consequential in quantifiable cost and time savings.

Outdoor atmospheres change with the time. New buildings are added, illumination designs evolve, and reflective surfaces appear where none existed before.

A fixed sensor may become misaligned as surroundings change, needing substitution or repositioning. A rotatable sensor head, though, can be reoriented during routine maintenance.

This competence outspreads product lifetime and drops total cost of ownership—key concerns for cities and infrastructure operators.

Table 1: Fixed Sensor vs. Rotatable Sensor Head

| Feature | Fixed-Direction Sensor | Rotatable Sensor Head |

| Orientation adjustment | None after installation | Adjustable after mounting |

| Installation tolerance | Low | High |

| Response to site variability | Limited | Excellent |

| Correction of misalignment | Reinstallation required | Simple rotation |

Does a Rotatable Sensor Head Add Complexity to the Product?

One of the most significant benefits of a rotatable sensor head is that it expands flexibility devoid of adding electronic or software complexity.

The alteration is purely mechanical. There are no regulation tools, configuration software, or learning curves. Installers trust on visual feedback and real-life observation to attain best orientation.

This simplicity guarantees dependability while upholding easiness of use across skill levels.

Table 2: Benefits of Rotatable Sensor Head in Outdoor Applications

| Benefit | Resulting Advantage |

| Directional adjustment | Accurate ambient detection |

| Reduced rework | Faster commissioning |

| Adaptable to changing environments | Longer service life |

| One design fits many sites | Simplified product selection |

Lead-Top Closing

At Lead-Top, product design initiates with real installation circumstances—not unrealistic assumptions. Swivel stem control replicates the trust that flexibility should be built into the structure, not added as a second thought.

The LT210CH series symbolizes this thinking by offering constant performance across diverse surroundings devoid of increasing complexity. By authorizing installers with adjustment ability, Lead-Top products attain dependability through flexibility.

A rotatable sensor head is not purely a convenience—it is a strategic design decision that addresses real-life inconsistency. Empowered by swivel stem control, it transmutes installation from an inflexible process into a flexible one.

For outdoor photo control applications, this flexibility leads to improved precision, faster installation, abridged maintenance, and enhanced long-lasted performance.

Eventually, recognizing that environments change—and designing products that respond intelligently to that change—is what separates functional hardware from truly reliable solutions.