Introduction

Recently, we have received frequent feedback from Brazilian customers regarding water ingress issues with locally purchased light control products during inclement weather, resulting in equipment malfunctions. Therefore, they are looking for light sensor manufacturers who can provide solutions. Outdoor street lights exposed to harsh environments for a long time are indeed susceptible to the invasion of rainwater and moisture, which not only affects the normal operation of the light sensor but may also cause equipment damage. So, how can we ensure that the installed light sensor does not get water in? Below, we will provide some practical suggestions.

Choose a light sensor with waterproof rating

Firstly, it is crucial to choose a light sensor with a high level of protection. The protection level of the light sensor is usually represented by the IP (Ingress Protection) standard. For outdoor street lights, it is recommended to choose a light sensor with an IP66 or higher protection level, which can effectively prevent dust and moisture from entering and ensure stable operation of the light sensor in harsh environments. Although waterproofing of light sensors is important, in order to reduce production costs, there are still products on the market with lower waterproof levels such as IP44 and IP54.

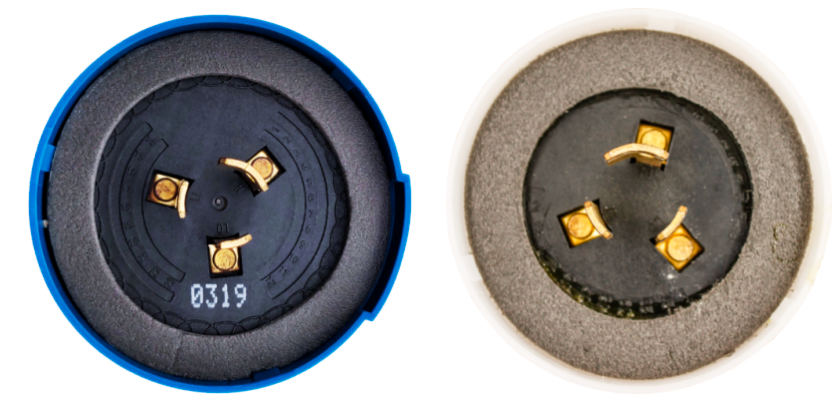

High waterproof grade products: IP66&IP67

Low waterproof level, light control: IP44&IP54

Ensure good sealing during installation

The correct installation steps are crucial to ensuring waterproof performance. When installing the light sensor, it is necessary to ensure good sealing of all joints, interfaces, and casings. It is recommended to use waterproof gaskets or sealants to further enhance the waterproof effect. If there are gaps in the joints of the lamps or light sensors, rainwater can easily infiltrate and damage the internal circuits.

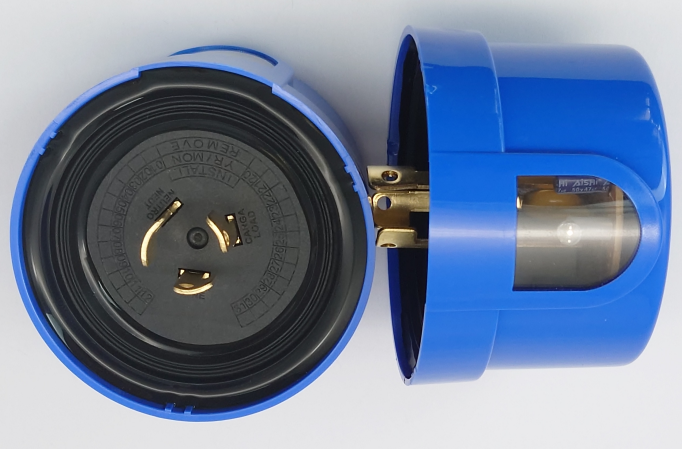

When the socket and light sensor are installed in the preset lamp holes, in addition to ensuring the waterproof performance of the light sensor itself, special attention should be paid to the tightness and waterproof effect between the socket and the light sensor. It is recommended that the waterproof standard should reach at least IP66 to ensure reliable operation of the equipment in harsh outdoor environments.

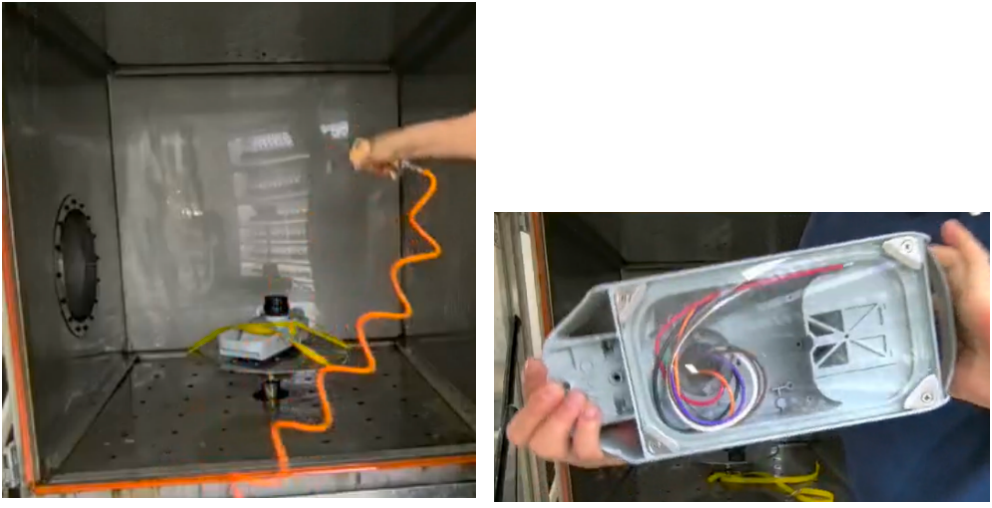

In order to provide a better user experience, Zhejiang Leadtop Electric Co., Ltd. has specially prepared a video to showcase the IP66 waterproof test effect of the light sensor and socket produced by our company after matching, for your reference.

When the lighting fixture does not have a pre drilled hole, the socket and light sensor need to be installed outside the fixture. In addition to ensuring the waterproofing of the light sensor itself and the sealing between the light sensor and the socket, additional waterproof protection measures need to be taken for the socket. These measures include:

- 1. Install a waterproof back cover at the bottom of the socket and seal it with waterproof glue to ensure that water does not enter the joint.

- 2. Use gland heads and waterproof cables to further enhance waterproof performance and prevent rainwater from entering the socket through the cables.

Through these additional protective measures, you can ensure that even when installing light sensors and sockets on the exterior of lamps without reserved holes, the equipment can still meet IP66 or even higher waterproof standards, effectively resisting harsh weather conditions and ensuring long-term stable operation.

Regular inspection and maintenance

Even if a high protection level light sensor is used, regular inspection and maintenance cannot be ignored. After installation, regular inspections should be carried out on the housing of the lamps and light sensors for signs of damage or aging, especially after the rainy season or extreme weather. If loose or aged seals are found, they should be replaced in a timely manner to maintain the waterproof performance of the equipment. Especially when the product is approaching its service life, it is necessary to strengthen inspection and replacement to ensure that the equipment can continue to work normally and avoid potential failures.

Use additional protective devices

In areas with heavy rainfall, additional protective devices such as waterproof covers or barriers can be considered for streetlights. These devices can provide secondary protection for the light sensor, further reducing the risk of water ingress.

Conclusion

To ensure that the street lamps with installed light sensors do not get water, it is crucial to choose light sensors with high waterproof levels, ensure good installation sealing, regularly inspect and maintain them, and take additional protective measures. Through these preventive measures, you can effectively extend the service life of street lamps and light sensors, reduce maintenance costs, and improve the reliability of equipment in harsh weather conditions.

Taking good waterproof measures can ensure that your street lights and light sensors maintain efficient and stable performance during long-term use, making urban lighting safer and more reliable.