Introduction

Outdoor lighting plays an important role in modern life, and how we see places after it gets dark as it guarantees safety and improves the usability of public and private spaces at night. But as important as it is, outdoor lighting in severe weather conditions can badly impact dependability as heavy rains can cause water ingress, dust can clog lenses, and summer heat shortens the lifespan of drivers and LEDs. The solution is present not only in designing strong lighting systems but also in choosing the right weatherproof LED lighting fixtures and installing properly protected photocell sensors. By selecting housings rated IP66/IP67 lights, municipalities and facility managers can ensure outdoor systems operate reliably through years of changing seasons.

Here we break down common weather-related challenges, explain how the right hardware mitigates risks, offer best practices for installation and maintenance, and demonstrate through case examples how to achieve lighting systems that truly withstand any environment.

Common Weather Challenges for Streetlights

Streetlights and outdoor lighting are 24/7 exposed to conditions that indoor fixtures never face. Understanding these challenges helps explain why failures occur and why robust design is critical:

- Heavy Rain and Snow

One of the greatest threats to electrical equipment is water. Poorly sealed housings let moisture to enter inside, corroding drivers, shorting circuits, and causing unexpected blackouts, snow and ice add pressure to fixtures and can lead to condensation inside housings once they melt.

- Fog, Dust, and Salt Spray

Salt particles in the air corrode metallic parts in coastal regions, as fog or industrial dust stays on lenses and sensors, reducing their sensitivity. A dirty photocell sensor may misread ambient light and keep lamps on during the day or off at night.

- Extreme Temperatures

LEDs can flicker or drivers can fail prematurely in harsh winters, while extreme heat speeds up the degradation of capacitors and electronic components, and without proper photocell sensor protection, sensors may respond unpredictably.

- UV Exposure

Plastic is broken down by direct sunlight, making housings brittle over time. Fixtures made of non-UV-stabilized materials may crack, allowing more dust and water ingress.

- High Winds and Mechanical Stress

Poles and fixtures must hold out against strong gusts, especially in open fields or coastal areas. Vibrations from wind and traffic can loosen connections, making outdoor light issues more frequent without proper reinforcement.

Takeaway: From water to UV, every environmental factor affects the performance of outdoor lighting systems. Being prepared for these risks is the foundation of long-lasting reliability.

Choosing the Right Sensor and Housing

One of the most effective ways to protect outdoor lighting is by attentively selecting both the photocell sensor and the luminaire housing, here’s what to look for:

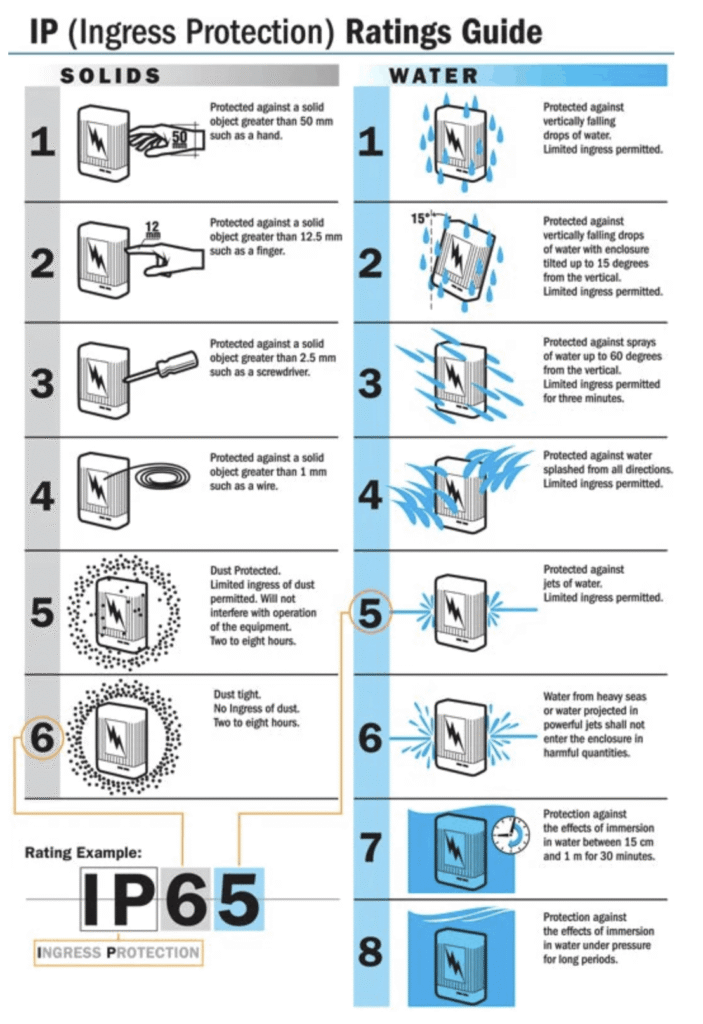

- Ingress Protection (IP Ratings):

Fixtures and sensors should carry at least IP65, but IP66/IP67 lights are chosen:

- IP66: Dust-tight and protected against powerful water jets.

- IP67: Dust-tight and protected against immersion in water up to 1 meter for 30 minutes.

- Durable Materials:

Housings which are made of materials like UV-resistant polypropylene or powder-coated aluminum last longer as they prevent cracking, yellowing, or deformation caused by sun exposure

- Surge Protection:

Outdoor lighting is at risk of voltage spikes from lightning or unstable power grids, quality sensors with integrated surge protection prevent failures and extend system life

- Temperature Ratings:

Select those components that are rated to operate between –40°C and +70°C, making sure that they perform in freezing winters and blazing summers, By combining weatherproof LED lighting fixtures along properly sealed photocell sensor protection, municipalities decrease the risk of failure while making sure of uniform lighting levels across entire neighborhoods or industrial sites.

Best Practices for Installation and Maintenance

Even the best-rated fixtures fail if installed poorly, but following these practices makes sure of long-term resilience:

- Correct Sensor Positioning

- Photocells should face open sky, free from obstruction by walls, trees, or other lights

- Avoid locations where artificial light sources can confuse the sensor

- Sealing and Mounting

- Use gaskets and weatherproof cable glands at all entry points

- Check torque specifications to prevent loose fittings that invite water ingress

- Regular Cleaning

- Sensors and lenses should be cleaned to get rid of dust or salt buildup

- A maintenance schedule every six months ensures great dusk-to-dawn function

- Routine Inspection

- Check for cracks, worn seals, or faded housings during inspections

- Verify surge protection devices are still intact, especially after thunderstorms

- Standardized Protocols

- For large installations, use pre-calibrated sensors and follow uniform mounting procedures

- Consistency prevents variation in performance across multiple lights in one project

Tip: Maintenance is not just about fixing failures, it’s about preventing them. A structured routine can add years to the life of outdoor lighting systems.

Case Examples: Coastal, Mountain, and Urban Projects

Different environments give unique challenges. Let’s examine how weatherproofing strategies adapt across regions.

- Coastal Projects

Salt spray accelerates corrosion, and in these areas, using IP67 lights with marine-grade coatings is important, photocells should be shielded with hydrophobic coatings to avoid the buildup of salt. - Mountain or High-Altitude Areas

Rapid temperature swings cause condensation inside housings, Fixtures that have breathable membranes and allow moisture to escape while keeping dust out are perfect. Surge-protected sensors avoid damage from lightning common at high altitudes. - Urban Centers

Smog, dust, and constant vibration from traffic affect both housings and sensors. Easy-to-clean enclosures and quick-access designs reduce maintenance time. Here, weatherproof LED lighting ensures consistent illumination for pedestrian safety.

Environmental Needs and Solutions

| Environment | Challenge | Recommended Solution |

| Coastal Areas | Salt spray corrosion, humidity | IP67 housing, anti-corrosion coatings, surge protection |

| Mountain Zones | Temperature swings, lightning | Thermally rated drivers, breathable membranes |

| Urban Projects | Dust, smog, vibration | Easy-to-clean housings, reinforced mounts |

Conclusion

Making sure of outdoor lighting extreme weather resilience needs a combination of smart planning, strong hardware, and consistent maintenance, by selecting IP66/IP67 lights, adding photocell sensor protection, and implementing regular cleaning and inspection protocols, municipalities and businesses can have reliable illumination that saves energy, enhances safety, and reduces costs.

Lead-Top’s range of weatherproof LED lighting solutions provides exactly this reliability, designed for rain, snow, salt spray, and extreme temperatures. Whether you’re upgrading a city street network or an industrial facility, our photocell-protected systems guarantee dependable performance under any condition.

Ready to weatherproof your lighting projects? Contact Lead-Top today to learn how our advanced fixtures and sensors can keep your streets and facilities bright, safe, and efficient in every season.

References: