Introduction

While Zhaga connectors often get attention for their interface standards, the humble nut quietly determines whether a lighting system lasts 5 years or 25. At Zhejiang Lead top Electric, our experience across thousands of global lighting control projects proves that material selection for these small components requires big thinking.

Zinc Lock Nuts: The Cost-Effective Workhorse

Price Advantage

Material cost: 33-50% cheaper than stainless steel

Ideal for municipal projects requiring 1M+ units

Manufacturing Excellence

5x faster die-casting production (verified by Lead Top’s production data)

99%+ pass rate for complex geometries

Surface Treatment Flexibility

Nickel plating (5-8μm) achieves 72h salt spray resistance

Chromium plating for enhanced urban acid rain protection (pH≥4.5)

▶ Lead Top Case:

2022 provincial capital smart streetlight project:

Used our zinc nuts + chrome plating

Zero corrosion reported in 3-year inspections

35% cost savings vs stainless steel

Stainless Steel Internal Tooth Lock Washers: The Premium Performer

Extreme Environment Performance

304/316 stainless steel passes 2000h 5% salt spray test

No red rust formation (vs 120h for plated zinc)

Mechanical Superiority

520MPa tensile strength (zinc: 280MPa)

Critical for bridges/tunnels with vibration risks

Lifecycle Economics

Dubai project data: 60% lower maintenance costs

30-year service life in coastal environments

▶ Lead Top Advantages:

Dual material options with no MOQ restrictions

Free material selection consultation

Custom solutions for special applications

The 4Q Selection Method

Answer these to choose right:

- Environment: C4 (industrial/coastal) or CX (extreme)? → Stainless

- Budget: Need >15% cost reduction? → Zinc + plating

- Lifespan: <10 years or ≥15 years?

- Vibration Risk: High mechanical stress? → Stainless

- Conclusion: Precision Engineering, Not Just Products

At Lead Top we engineer solutions where:

✓ Every $0.8 premium for stainless buys decades of reliability

✓ Every zinc alloy saving funds extra infrastructure (e.g., 500m more lighting)

Why global clients choose us:

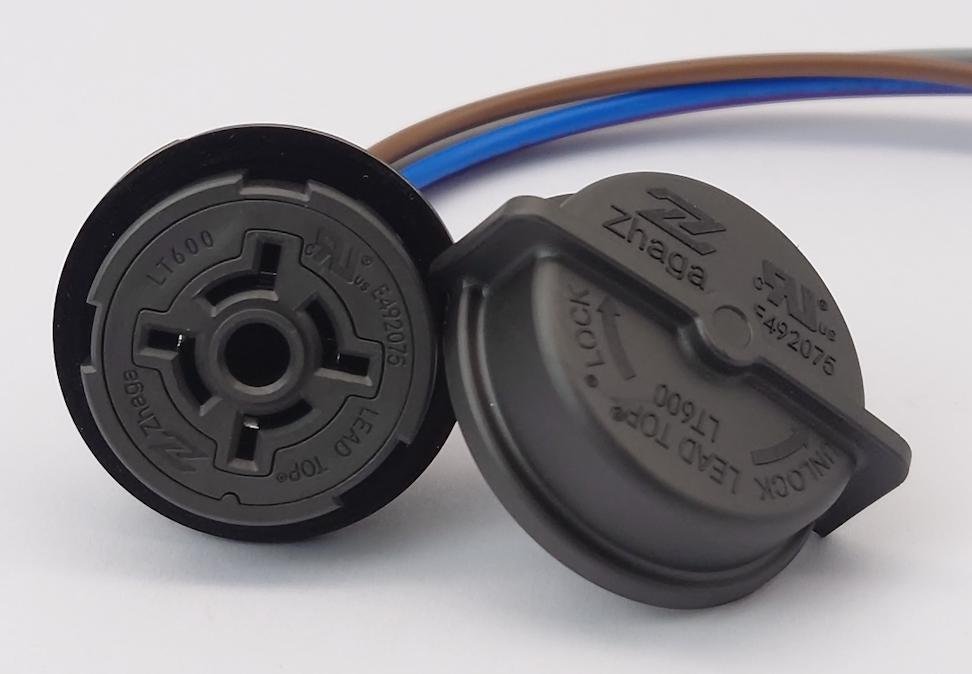

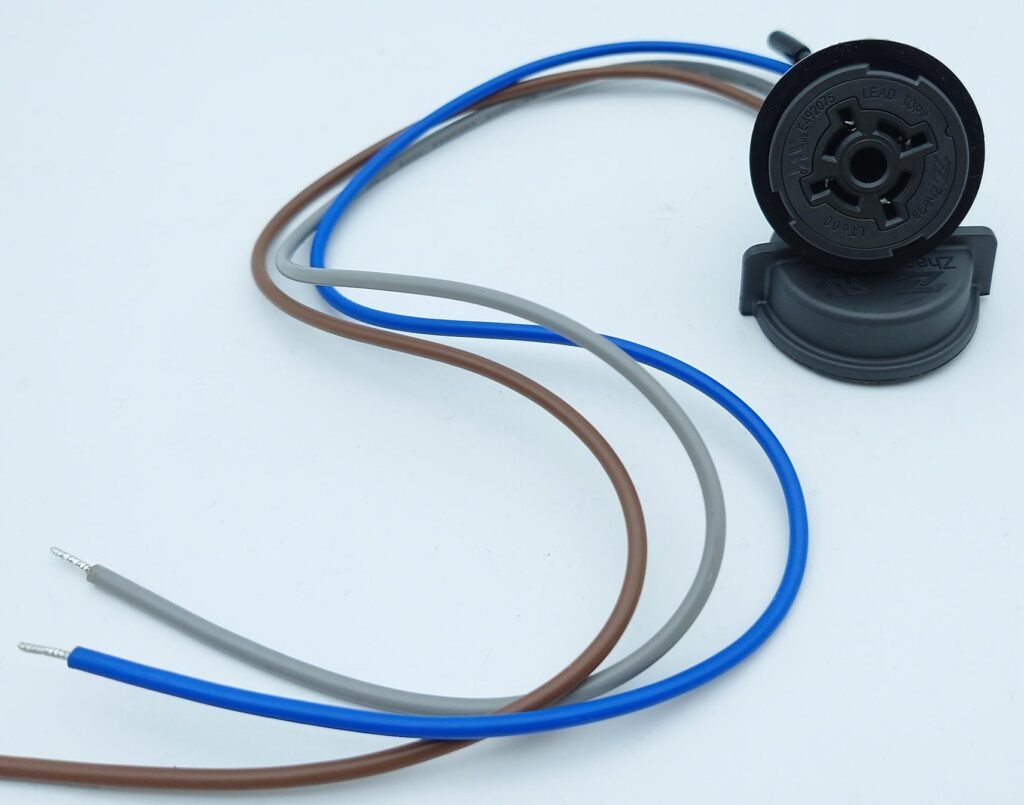

Zhaga-compliant components with unmatched material expertise

From prototype to mass production with zero MOQ barriers

Data-driven selection tools for optimal TCO