Surge voltage is a common but potentially serious damage phenomenon in electrical equipment and systems. To protect these devices, engineers typically use metal oxide varistors (MOVs) and surge protection devices (SPDs). Although both are used to protect against surge voltage, there are significant differences in their working principles, structures, and application scenarios. This article will explore in detail the differences between MOV and surge protection, and explain their applications in light control products.

Working Principle

MOV (Metal Oxide Varistor):

MOV is a varistor whose resistance value adjusts rapidly with changes in voltage. When a surge voltage appears in the circuit, the resistance of the MOV decreases rapidly, shunting the overvoltage through it, thereby protecting the equipment from damage. MOV has high impedance under normal operating voltage, and exhibits low impedance when a surge voltage appears, thereby effectively shunting the surge current.

In light-controlled products, the withstand current of MOV is usually 10KA, which means that the maximum surge current it can withstand is 10KA. In addition, in some application scenarios, the parameters of MOV may reach 20KA/10kV, which enables it to cope with higher levels of surge voltage.

Surge Protection Device (SPD):

SPD is a complex protection device, usually composed of multiple components (such as MOV, gas discharge tube, diode, etc.) to handle surge voltage. Through a multi-level protection mechanism, SPD can not only cope with surge voltages of various types and intensities, but also ensure that electrical equipment is effectively protected under extreme conditions.

According to ANSI standards, the maximum level (Extreme Level) of SPD can reach 20KV/10KA, which means that under the most extreme conditions, SPD can also provide reliable protection to protect equipment from surge current.

Structure and composition

MOV:

MOV is a simple unit device, usually made of zinc oxide material, with a compact structure and easy to integrate into various electrical equipment. It is usually directly soldered on the circuit board, with a small size, suitable for application scenarios with limited space.

SPD:

SPD is composed of multiple protection components, usually designed as an independent module or box, suitable for installation in a distribution cabinet or electrical panel. The SPD is relatively large in size, but it can provide more comprehensive and powerful protection, especially suitable for industrial and commercial environments that require high-level protection.

Application scenario

MOV:

MOV is mostly used in scenarios that require simple and economical overvoltage protection, such as household appliances, power adapters, and circuit boards. Due to its simple and economical characteristics, MOV is very common in these scenarios. However, MOV has limited durability and may deteriorate or even fail after experiencing multiple strong surge events.

In light control products, MOV is usually designed to withstand a surge current of 10KA, which meets the maximum level requirements in the ANSI standard. For more demanding applications, the parameters of the MOV may be designed to be 20KA/10kV to cope with larger surge currents.

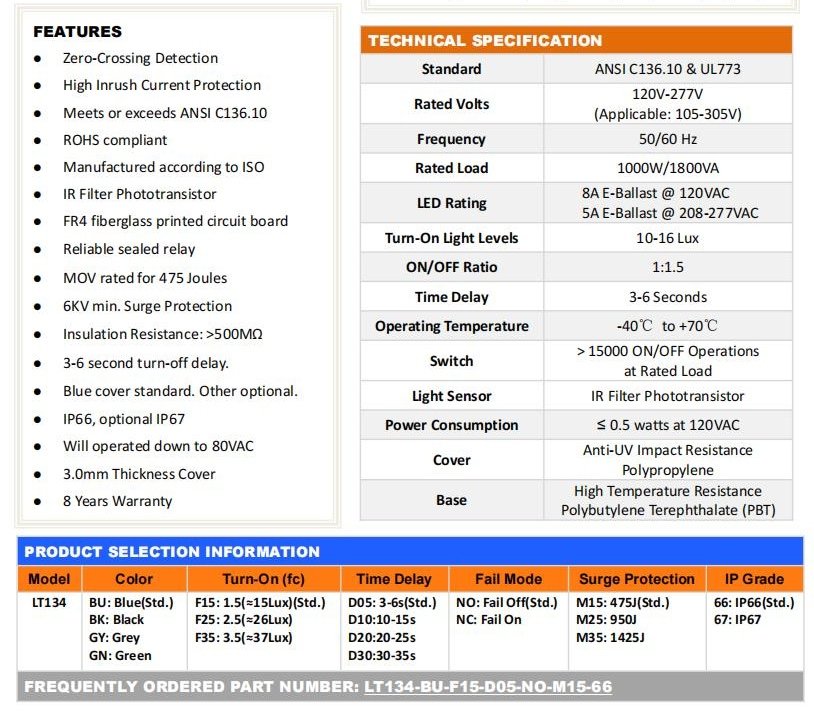

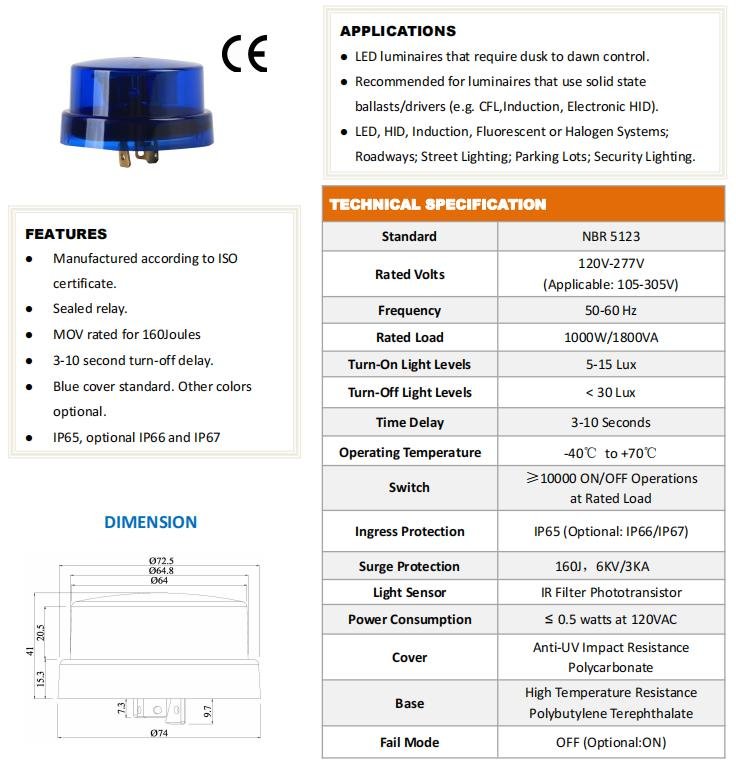

For example, the LT104 photocontroller from Zhejiang Leadtop Electric uses a 160 Joule MOV and is equipped with surge protection (6KV/3KA) that complies with the ANSI C136.10 standard. In order to meet the needs of customers for different projects, we also provide a variety of MOV configurations, including 160 Joule, 475 Joule, 950 Joule and 1425 Joule.

SPD:

SPD is widely used in places that require high-level protection, such as industrial power systems, communication equipment and data centers. SPD can not only cope with various types of surge voltages, but also provide multi-level protection to ensure the safety and stability of equipment under extreme conditions.

SPD devices are usually designed to withstand higher surge levels, such as 20KV/10KA. Such a design ensures that it can still provide effective protection under extreme conditions and is an essential protective measure in high-demand environments. The maximum surge current of light control products is 10KA, which meets the highest level of ANSI standards (20KV/10KA). Zhejiang Leadtop Electric‘s LT124 and LT134 products both meet this standard and can cope with various complex lighting projects and environments. These two products are also the product models we developed and designed for municipal bidding projects. We have successfully helped many partners successfully win bidding projects with this product.

4. Life and Maintenance

MOV:

MOV may deteriorate after multiple surge events, so it needs to be inspected and replaced regularly. Its life depends on the frequency and intensity of the surge. Once the MOV fails, it usually opens or shorts, so its status should be closely monitored in actual applications.

SPD:

SPDs usually have a longer service life and are designed with a status indicator function to show whether its protection function is intact. Because SPDs are composed of multiple protection components, they can still provide a certain degree of protection even if some components fail. However, regular maintenance and inspection are still important steps to ensure the effective operation of SPDs.

Conclusion

Both MOVs and SPDs are key surge protection components, each suitable for different application scenarios. MOV is widely used in various small electrical equipment due to its simple structure and low cost, while SPD is suitable for industrial and commercial environments that require a higher level of protection. In light control products, the MOV’s withstand current is usually 10KA, while in more demanding applications, the MOV’s parameters may reach 20KA/10kV. At the same time, the design of SPD usually meets the extreme level (20KV/10KA) in the ANSI standard to cope with the most demanding surge conditions.

Understanding and correctly selecting the appropriate surge protection device can not only extend the service life of the equipment, but also significantly improve the safety and reliability of the system.