Introduction: The Overlooked Critical Detail

When purchasing NEMA sockets, many buyers often focus only on visible parameters such as voltage, current, and materials, while overlooking the critical detail of the gold plating thickness on the metal contacts. Have you ever encountered this issue: the same type of socket, some can last stably for 10 years, while others fail or even burn out after just 2 years? One of the key factors behind this is the gold plating thickness. This article will delve into the standards for gold plating thickness and reveal its significant impact on socket lifespan and electrical safety.

What is Gold Plating Thickness? Why is it So Critical?

Definition

Gold plating thickness relates to the thickness of the gold layer on the surface of the socket’s metal contacts, usually measured in micrometers (μm). It is one of the important indicators for evaluating socket quality.

Functions

Anti-Oxidation: The gold layer stops oxidation of the metal contacts effectively and efficiently, avoiding poor contact.

Enhancing Conductivity: Gold has magnificent conductivity, ensuring low resistance and stable electrical connections.

Reducing Wear: The gold plating layer can withstand frequent plugging and unplugging, extending the lifespan of the contacts.

Criticality

Gold plating thickness directly influences the performance, lifespan, and safety of sockets. It is an essential element in determining whether stuff can operate firmly over the long term. Inadequate gold plating thickness can result in rapid oxidation, wear, and even safety dangers, while sufficient gold plating thickness can notably extend the socket’s lifespan.

The Impact of Gold Plating Thickness on NEMA Sockets

Lifespan

Insufficient Gold Plating Thickness (e.g., less than 0.4 μm) brings about swift oxidation and deteriorates the contacts, reducing the lifespan of the socket.

Adequate Gold Plating Thickness (e.g., 0.8 μm or more) can notably increase the socket’s lifespan, even up to 10 years or more.

Performance

Thin Gold Plating extends contact resistance, creating heat generation, loss of energy, or even exhaustion.

Proper Gold Plating Thickness confirms firm electrical connections and reduces failure rates

Safety

Insufficient Gold Plating may cause poor contact, sparking, overheating, and increase fire risks.

Compliant Gold Plating Thickness significantly enhances electrical safety.

International Standards for Gold Plating Thickness

IEC Standards

General Applications: Minimum 0.4 μm.

High-Reliability Applications: Recommended 0.8 μm or more.

ASTM Standards

Pure Gold Plating (Type I): Minimum 0.4 μm.

Hard Gold Plating (Type II): Minimum 0.8 μm.

High-Reliability Applications (e.g., Aerospace): Recommended 1.25 μm or more.

UL Standards

While no specific thickness is explicitly defined, UL generally requires that the gold plating layer meet electrical and safety performance standards, with 0.4 μm commonly adopted as the minimum.

Industry Practices

General Commercial Applications: 0.4 μm.

Industrial or High-Reliability Applications: 0.8 μm or more.

Zhejiang Lead Top Electrical Co., Ltd.: The Industry Benchmark for Gold Plating Thickness

Company Introduction

Zhejiang Lead Top Electric Co., Ltd. specializes in the design and manufacturing of high-quality NEMA sockets, committed to providing customers with safe, reliable, and durable electrical connection solutions. We understand the importance of gold plating thickness to socket performance and therefore adhere to high standards in product design and manufacturing.

Advantages in Gold Plating Thickness

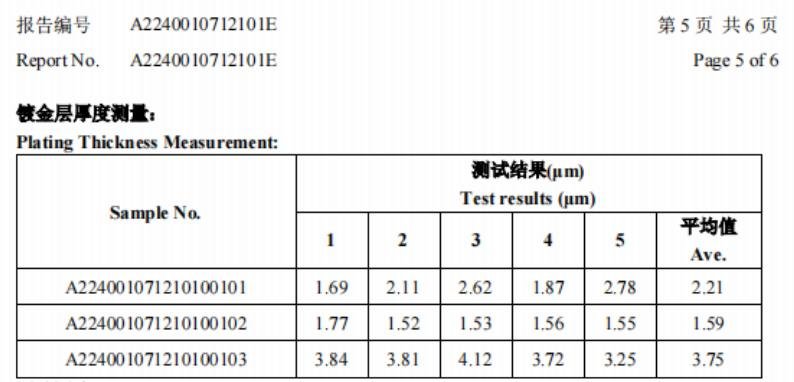

The gold plating thickness of our NEMA socket metal contacts reaches 1.6-3.8 μm in tri-annual testing, with a few products even attaining 4.12 μm, far outdoing industry standards.

This high standard of gold plating thickness ensures long-term stability and reliability of sockets in extreme environments, significantly extending their lifespan.

Customer Value

Choosing Lead Top Electrical products means opting for longer lifespans, lower maintenance costs, and higher electrical safety.

Our sockets are broadly used in high-performance fields such as industrial, medical, and aerospace applications, gaining the trust of customers.

How to Determine the Gold Plating Thickness of NEMA Sockets?

Check Product Specifications

Reputable manufacturers will clearly specify the gold plating thickness in product documentation. Be sure to read the relevant parameters carefully during procurement.

Third-Party Testing

Conduct gold plating thickness testing through professional organizations (e.g., SGS, TÜV) to ensure compliance with standards.

Observe Appearance and Performance

Contacts with plentiful gold plating usually exhibit a more uniform and bright gold color.

Sockets with insufficient gold plating may show signs of oxidation, blackening, or poor contact after some use.

How to Avoid Insufficient Gold Plating Thickness When Purchasing?

Choose Reliable Brands

Go for well-known brands or products that come with certifications (e.g., UL, IEC) to guarantee quality and reliability.

Define Requirements

Select the appropriate gold plating thickness based on the application scenario (general commercial, industrial, or high-reliability).

Request Test Reports

Ask suppliers for gold plating thickness test reports or certification documents to ensure compliance with standards.

Avoid the Low-Price Trap

Low-priced products often cut corners on gold plating thickness, leading to higher long-term costs. Pick high-quality products to ensure true cost-effectiveness.

Conclusion: Small Details Make a Big Difference—Gold Plating Thickness Affects Socket Lifespan

Gold plating thickness is not an optional parameter but a critical factor directly determining the lifespan and stability of sockets. When purchasing, do not be misled by “low prices.” Sockets with not enough gold plating may result in significantly higher long-term maintenance costs or even safety hazards.

Zhejiang Lead Top Electrical Co., Ltd.‘s NEMA sockets, along a gold plating thickness of 1.6-3.8 μm, provide customers with high-quality products that far exceed industry standards, ensuring long-term stable operation of equipment. Choosing Lead Top Electrical means choosing safety, reliability, and durability.

The next time you select a NEMA socket, will you reconsider the hidden factor of gold plating thickness?