It is a device that can automatically adjust the switching status of lighting equipment according to the ambient light intensity. However, the photoresistor in the light controller may drift in resistance, which affects its performance and accuracy.

What is resistance drift?

Resistance drift refers to the phenomenon that the resistance value of a photoresistor changes over time. This change may be gradual or sudden. Resistance drift may cause the light controller to misjudge the ambient light intensity, thereby affecting its accuracy in controlling lighting equipment. The longer the time, the greater the change, which will eventually lead to turning on the lights earlier and earlier and turning off the lights later and later, which is not energy-saving.

What are the causes of resistance drift?

1.Environmental factors: Long-term exposure of the photocontroller to different environmental conditions, such as sunlight, rain, humidity, etc., may cause the material of the photoresistor to age or be damaged, causing resistance drift.

2.Temperature changes: Temperature changes will also affect the performance of the light controller. Temperature that is too high or too low may cause the resistance value of the photoresistor to change, causing the resistance value to drift.

3.Electrical factors: Voltage and current changes in the circuit may affect the photoresistor, resulting in resistance drift

How to avoid the impact of resistance drift?

1.Regular inspection and maintenance: Regularly check the status of the light controller, clean and maintain the photoresistor to ensure its normal operation. Or replace the light controller regularly, for example, update it every 3 years.

2.Environmental control: Try to avoid exposing the light controller to extreme environmental conditions for a long time, such as long-term ultra-high temperature, humidity and direct sunlight.

3.High-quality materials and manufacturing processes: Choose high-quality light controller products, which use high-quality materials and advanced manufacturing processes to reduce the risk of resistance drift. For example: semiconductor silicon photoelectric components for light controllers.

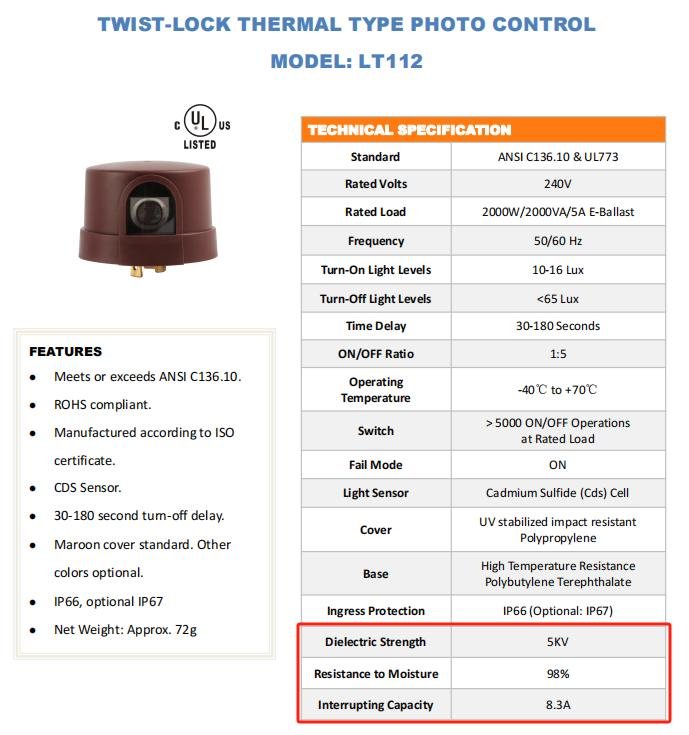

4.Circuit design: Design a stable circuit for use by the light controller to avoid sudden changes in voltage and current. For example: use high configuration relays. For example, Zhejiang Leadtop Electric’s light controller LT112 is designed with high-quality materials and circuit design to reduce resistance drift.

A: Interrupting Capacity:8.3A

Interrupting Capacity: Interrupting capacity

The interrupt capacity of a photocontroller indicates the maximum current or voltage level it can safely interrupt. This is essential to protect circuits and equipment from overload or failure. If the light controller cannot withstand excessive current or voltage in the circuit, it may cause equipment damage or safety hazards.

B. Dielectric Strength: 5KV

Dielectric Strength: Dielectric strength, its main function is to ensure that safety problems such as electric shock or leakage will not occur during normal use. Can be ensured to work safely in specific electrical environments without safety hazards

What kind of light controller will not have resistance drift?

The photocontroller of semiconductor silicon photoelectric components will not have resistance drift. For example, Zhejiang Leadtop Electric’s LT134, LT124, LT124L, LT104 and other electronic light controllers all use semiconductor silicon photoelectric components, which will not produce resistance drift, ensuring that the light controller will remain stable during long-term use. Stable performance and reliability.

Why does the photocontroller of semiconductor silicon photoelectric components not have resistance drift?

- Material stability: Semiconductor silicon is a highly stable material with good chemical and physical stability. Its crystal structure and electronic properties are not prone to change under normal use conditions.

- Structural design: Semiconductor silicon photovoltaic components usually adopt optimized structural design, including appropriate electrode layout and material selection, to minimize the impact of external environmental factors on device performance. This design helps reduce the possibility of resistance drift.

- Electronic properties: Semiconductor silicon has stable electronic properties, including carrier mobility and diffusion coefficient. These properties are not prone to significant changes over time or environmental changes, so they will not cause resistance drift.

conclusion

The photocontroller of semiconductor silicon photoelectric components will not produce resistance drift. For some projects that need to be used in special environments or have special requirements for light controllers, high-quality materials and special circuit designs need to be selected.

To choose a suitable light controller, you need to contact a professional light controller manufacturer. Zhejiang Leadtop Electric Co., Ltd. can tailor the optimal lighting solution for you. We support sample customization and are professional manufacturers willing to make various attempts to design customers’ products.